Our Products

Contact Information

4F., No.82, Luke 5th Rd., Luzhu Dist., Kaohsiung City 821, Taiwan (R.O.C.)

Tel: 886-7-6955325

Fax: 886-7-6955326

Electroluminescence Image system

Model: LSEL-R/ LSEL-M/ LSEL-C

Category: Automatic/Industrial Machines & Equipments / Testing Equipment / Inspecting/Measuring Instrument and Parts

Characteristics

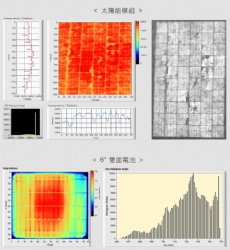

● Qualitative analysis of 2D EL intensity distribution

● Correlation of implied Voc from EL

● Different injection current dependent uniformity analysis

● Controllable adjustment related parameters of camera

● Controllable power supply

● Can set the ROI image area

● Format of output image: JPEG, BMP, TXT., RAW Data etc.

● With Video/Image mode

● Defect inspection and shunting points of absorber material (optional)

● Integration of temperature control platform (optional)

● Light induced degradation (LID) investigation (optional)

● Combo system with PL image measurement for series resistance (Rs) anal-

ysis (optional)

● Dark current-voltage (IV) curve measurement and parameters

extraction (optional)

Specifications

Electroluminescence Image System

The electroluminescence technology is biased the forward current to the solar cell such as LED and the emitting wavelength is correlated to band-edge emission or defect asssistance emssion. The EL intensity is directly correlated to defect density and recombination coefficient. The less of the part of defect, the luminescence intensity will be stronger, and the more part of the defect, the luminescence intensity will be weaker. The electroluminescence image can reveal the material of the solar cell module defects, such as material defects, sintering wave, contamination, micro-crack and broken finger etc. The EL image of solar cell is dependent on injection current level, and used to evaluate the optimized cell/module structure for high efficiency approach. For absorber with the same band gap, the EL intensity is proportional to open circuit voltage (Voc). The quantitative analysis of EL image has high benefit for process control instead of qualitative inspection. The reliability and aging of solar cell/module can also be studied by EL image system for the investigation of degradation parameters. The defect, crack, and shunting points can also be obtained. The sheet resistance (Rs) distribution can be extracted by the combination of PL and EL images with proper measurement condition.

* Luminescence Photo Energy of Solar Cell at Room Temperature,Corresponding Energy Gap of Material and Radiative Recombination Mechanism

|

Type

|

Band gap (eV) |

EL emission peak (eV) |

Recombination mechanism

|

|

c-Si |

1.12 |

1.04 |

Phonon assistance |

|

GaAs |

1.42 |

1.4 |

Band-to-band |

|

a-Si:H |

1.5~2.1 |

1.5~2.1 |

Phonon assistance |

|

CdTe |

1.5 |

1.3~1.5 |

Band-to-band, Defect-related |

|

CIGS |

1.04~1.68 |

0.8~1.68 |

Band-to-band, Defect-related |

|

InGaP/ InGaAs/Ge |

1.8 |

1.8 |

Band-to-band |

|

1.43 |

1.4 |

Band-to-band |

|

|

0.66 |

0.62 |

Phonon assistance |

>>> Different types of product <<<

| Solar Cell | Solar Module | Outdoor Solar Module |

| LSEL-M | LSEL-C |

Featured products

-

Spectral Response / Quantum Efficiency Measurement System

-

Photo-Luminescence and Efficiency Measurement System

-

Reference Solar Cell

-

Laser Beam Induced Current / Voltage (LBIC/LBIV) Measurement System

-

PL & EL Luminescence Spectrum System

-

Photoluminescence Image System

-

Raman Spectrum Measurement System