Our Products

- Blowers (7)

- Heat Sealing (1)

- Pneumatic Valves (1)

- Other Machinery (1)

Contact Information

Foshan City, Guangdong Province, China Mainland

Tel: 86-188-23126158

Fax: [email protected]

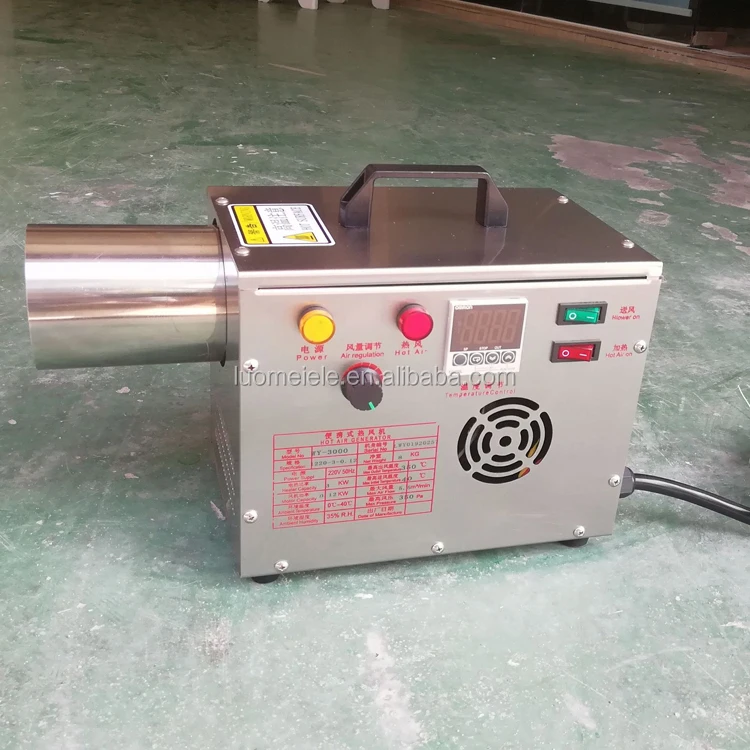

Portable Hot Air Blower / Air Heater / Industrial Hot Air Generator

Model: 5000

Category: Machinery Parts and Components / Machinery Parts and Components / Blowers

Characteristics

ring blower, medium pressure centrifugal blower, low pressure centrifugal fan, industrial hot air heater, explosion-proof fan, air knife, air filter, pressure relief valve, silencer, air pump, pond aerator, etc

Specifications

1. Technical Paramater

Contact

luomeiele(at)163.com, wechat/whatsapp: 008618823126158

| Model: WY-2000,WY-3000,WY-4000,WY-5000 | |||

| Voltage | 220V single phase | Max outlet temperature | 350℃ (reducing air volume) |

| Heater power | 2KW/3KW/4KW/5KW | Max inlet temperature | 40℃ |

| Fan power | 0.12KW | Max Airflow | 5.5m3/min |

| Heater material | 2080 Nickel chromium wire | Maximum pressure | 350Pa |

| Environment temperature | 0~40 ℃ | Dimension | below attached picture |

| Environment humidity | 80% R.H. | Net Weight | 8KG |

| Note: | If you want to change outlet diameter,please contact us,conventional 89mm | ||

2. Product Introduce

Portable industrial hot air blower are generally composed of four parts: a heater, a fan, a temperature control system, and a cabinet.

The heater part is made of pure 2080 nickel-chromium high-efficiency heating wire, high-quality high-temperature stainless steel casing, lightweight crystal insulation fiber blanket, 95 porcelain wiring board and other components. It has the characteristics of fast heating, small thermal inertia, precise temperature control and long service life. (Our heater core components use imported pure 2080 nickel-chromium alloy materials, some industrial enterprises have selected iron-chromium-aluminum heating materials, nickel-chromium materials, reclaimed silk, or inferior nickel-chromium wire to impersonate 2080 pure nickel-chromium wire, thereby reducing production. Cost. In application, generally used in three months or six months, the durability, stability, heat generation, accuracy and other aspects of the two products will have essential differences, which may lead to the loss of maintenance value of the product. Causes a production safety incident.)

The fan part is uniquely designed with low noise, can recycle hot air, and is energy efficient. Different wind pressure fans can be configured according to the actual needs of the user, which is flexible and practical. The fan air volume can be adjusted according to production needs.

The hot air blower is suitable for heating and drying of the plant, heat source equipment in the drying room and heating in a small air flow area. Various industrial plants, workshops, steelmaking, coal mine heating and heating, preheating heating and drying of various construction sites, drying of pipeline anti-corrosion inner walls, speeding up the drying of paints, heating and warming in winter construction sites, preheating of machines Warm up. Chemicals, plastics and other products are dry, food is dried after cleaning, and heat shrinkable packaging has examples of use.

3. Product display

Featured products

-

Turbo Blower / Medium Pressure Centrifugal Fan / Aluminum Alloy Blower

-

High Pressure Vortex Gas Pump Ring Blower Side Channel Fan

-

650℃ Industrial Electric Air Heat Gun Hot Air Shrink Gun Dryer

-

Noise Reducer Stainless Steel Air Silencer Ring Blower Muffler

-

RV-01 RV-02 Plastic Pressure Relief Valve For Ring Blower

-

Blower Air filter barrel vacuum pump inlet filter element

-

550W fume extractor smoking exhaust fan centrifugal blower for laser cutting machine