Our Products

Contact Information

High tech district, CHANAN TOWN, Dongguang CITY, GUANGDONG, CHINA

Tel: 86-769-23716588

Fax: 86-769-85379396

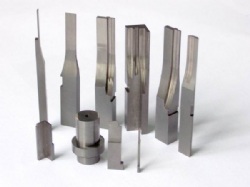

cnc optical profile grinding

Model: gls-5p

Category: Mold and Die Industry / Pressing Molds / Computer Peripherals

Characteristics

Precision carbon tungsten hard alloy product (punches and dies)Purpose of Product:apply in the punching mould and sophisticated wear-resistance parts in use of molding of precision parts, such as various IC, electronic communication, electrical appliances, micro motor, digital products, and printing and facsimile equipment.Maximum Manufacturing Precision of Product:maximum precision±0.001 mm (±1 μm)Product’s manufacture processing features:

be able to process screw thread hole on the tungsten steel precise parts

be able to process the tungsten steel precision pieces in bulk in a short period;

be able to polish the tungsten steel precision piece to specular surface.

carry out precision coating treatment to the surface, such as TiC, AlTiN, TiCN, and DLC so as to increase the wear resistance performance and prolong the service life.

Materials of the product:CD650,CD750,AF1,F10,V30,V40,SF12,KF15 are recommended for electronic types (semiconductor IC Lead Frame and connector); and GF20,GF30,KD15,KD20 are recommended for electric appliance category (thick materials punching). 。

Specifications

We use a formal quality system to manage the overall quality process, and use precision measurement facilities by a well-trained employee team. All tooling and parts produced at our facilities are constantly monitored by our Quality Assurance Department to meet your specifications including those for material, dimensional accuracy, surface finish, molding standard, inspection and packaging. Our quality system is focused on the customer requirements at all the times.

Following strict quality control procedures, our products are inspected at every stage of the production process: drawing auditing, copper electrode tests, EDM tests, wire incising tests, milling machine processing test, finished mold product test and pre-shipment test, so as to ensure the quality will meet the international criteria and satisfy the customers.

Featured products