Our Products

- Other Machinery (4)

- Other Printing Machines (2)

- Label Printing Machines (2)

- Hot Stamping, Printing & Embossing Machines (1)

Contact Information

No.225, Ren’ai Rd., Bali Dist., New Taipei City 249, Taiwan

Tel: 886-2-26101155

Fax: 886-2-26105751

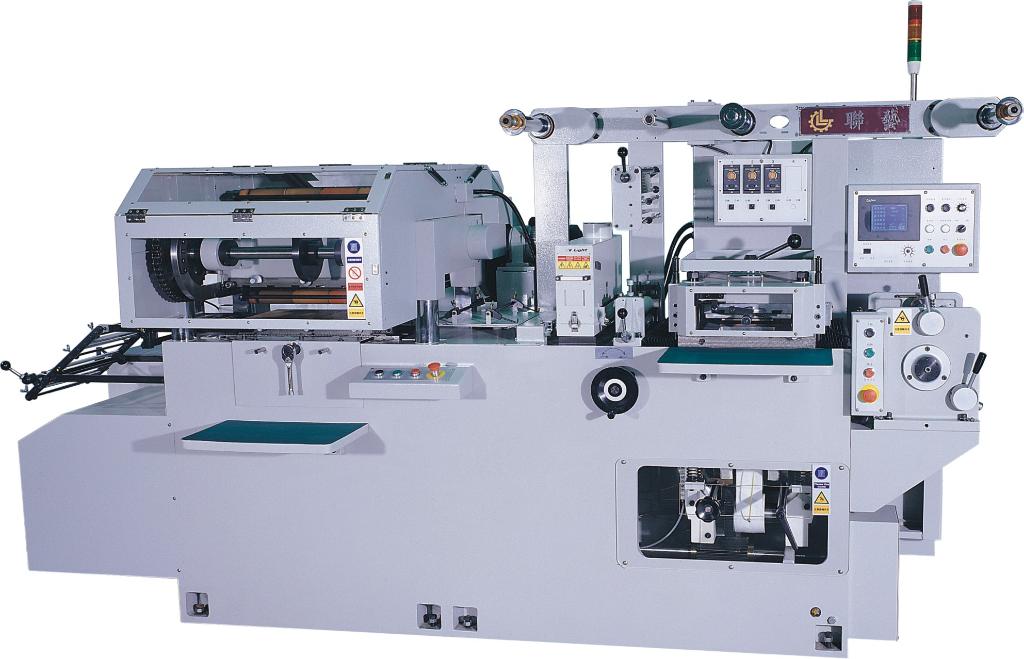

LLR-300 full rotary / intermittent label printng machine

Model: LLR-300

Category: Packaging, Printing, Food & Pharmacy Machinery / Printing Presses / Other Printing Machines

Characteristics

The new features of LLR-300 with no one else has

1. Improved ink supply system

A micro adjusting knob controls the interlocking ink transferring roller supplies of the ink precisely. When increasing or decreasing the printing speed, the operator can simply adjust the knob by 2 fingers. And there is no necessity to remove any roller while cleaning the ink fountain.

2. One of CE approved safe features

No matter when or where operator is working, he/she is well protected by the safety devices connected with every roller and moving part.

3. Precise printing unit adjustment

Equipped with linear tracking bearings on the base of printing unit, it allows for a smooth and precise registration, achieving a perfect printing.

4. User friendly (Human-Machine Interface)

A well programmed machine-user interactive communicating screen (HMI) helps even a new operator to properly follow correct instructions and select the desired options. Its totally user friendly design really reduces training cost.

5. Computerized intermittent feeding control

On each side of the machine, unwinder and rewinder both have a servo motor analyzed by computer which automatically controls feeding and pulling speed and also conducts accurate intermittent movement.

6. In-line UV dryers

A UV dryer is located after each printing and UV varnishing unit, and each UV dryer is capable to detect the printing speed and to adjust its output accordingly.

7. Printing without double image and gear mark

A set of triple anti-shadow rollers completely eliminates any possibility of ghost image and gear mark occurred in each printing unit.

8. All purpose plate cylinder

Special plate cylinder setting is designed for various label production, it also make replacement of plate cylinder extremely quick ad much more convenient.

9. Widely usable UV varnishing unit

The optional machine mount UV varnishing unit is able to perform whole image area varnishing or pattern varnishing for photopolymer plate.

10. Improved impression cylinder adjustment

Perfect horizontal impression cylinder is well supported and can be adjusted simply by a control knob.

11. Rotary die cutting unit

Optional heavy duty rotary die cutter with magnetic cylinder ensures the precise cutting at high speed printing.

CE Certification ( by Germany TUV & U.K. SGS )

Patent Certification ( Printing construction , Lamination unit )

Specifications

LLR-300 SPECIFICATIONS :

Max. paper width:300mm

Max. printing width:300mm

Max. printing area:240mm X 300mm (Full Rotary)210mm X 300mm (Intermittent)

Max. printing speed:50m/min 12,000 imp/hr , 200 rpm, Depending on the printing material

Printing colours

4 to 8 colours ( 4 = 4 colors stations ...etc )

Machine weight:(Approximately) 6,000kgs

SPECIFICATIONS OF OPTIONAL ACCESSORIES :

1.V = UV Varnish station

Max. paper width:300mm

Max. speed:200imp/min

Depending on the printing speed

Machine weight:Approximately 150kgs

2.R = Rotary die-cutter station

Range of cutting:240mm X 280mm

Max. speed:200imp/min

Depending on the printing speed

Machine weight:Approximately 150kgs

3. L = Lamination unit ( Patent )

4. Cold stamping unit

5. B = Back side printing station

6. W = Web Inspection system

Featured products