Our Products

- Other Machinery (4)

- Other Printing Machines (2)

- Label Printing Machines (2)

- Hot Stamping, Printing & Embossing Machines (1)

Contact Information

No.225, Ren’ai Rd., Bali Dist., New Taipei City 249, Taiwan

Tel: 886-2-26101155

Fax: 886-2-26105751

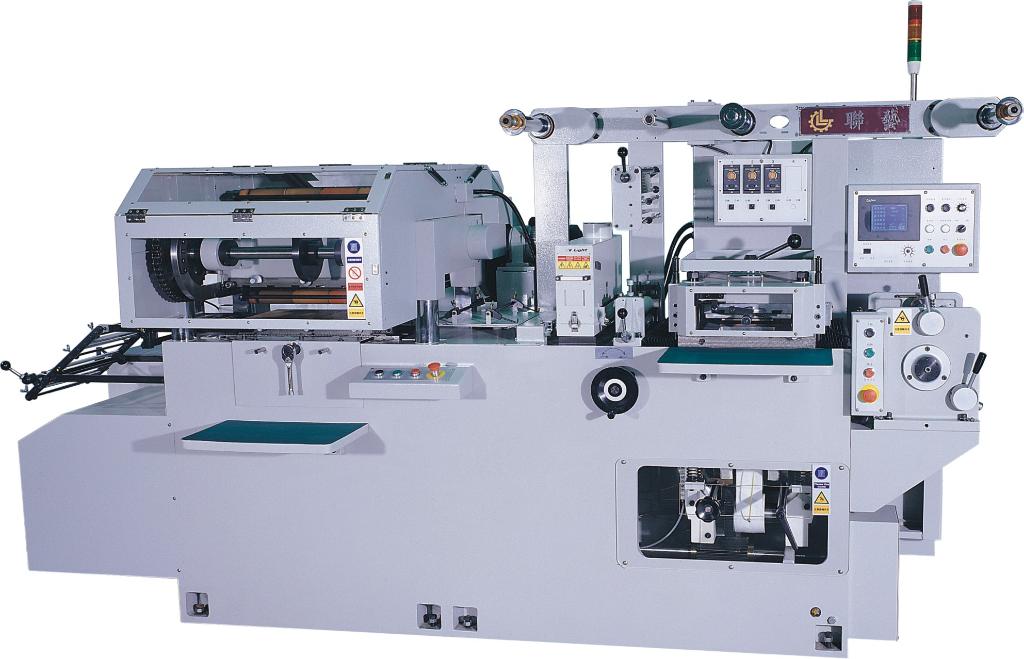

Twin stations HS & FD specialize machine

Model: HL-300

Category: Packaging, Printing, Food & Pharmacy Machinery / Printing Presses / Hot Stamping, Printing & Embossing Machines

Characteristics

HL-300 can coherent with LLR-300 after printing the product follow up right through to process hot-stamping, die-cutting, lamination and to collate the waste material.

L-300 can process the electron product and doing duplication lamination.

It has computer hold puncher and double hot-stamping unit could choose.

HL-300 can do precise over printing on double colour hot-stamping.

HL-300 can finish process the product independently.

***The basic units on machine table station is Flat-bed Die-cut unit & Hot stamping unit ( called HL-300 ) or Twin Flat-bed Die-cut units ( called LL-300 ) or Twin Hot stamping units ( called HH-300 )

or Flat-bed Die-cut unit & Computer sprocket pounching unit ( called LD-300 ) or Hot stamping unit & Computer sprocket pounching unit ( called HD-300 ) or Twin Computer sprocket pouching unit ( called DD-300 )

***Above units after you choose , the others you can buy the tool mold as optional

***The basic units also : Twin Lamination unit , Second Pass unit , Unwinder

***Applicable with LLR-300 Full rotary/ Intermittent printing machine connected both

in-line or out-line

***Or working independently connected with RV-270 Vertical Rewinder or RH-300 Horizontal Rewinder or S-300 Sheeter

Specifications

Machine weight : around 2,500 kg

3. Machine function : Feeding paper – Lamination – Hot stamping – Lamination – Die-cut

4. Machine construction : individual machine body

5. Spec.

ITEM Specification

Lamination ways Laminate with OPP film mantle stick on

Lamination material OPP film, adhesiveness material

OPP film max. width 300mm

OPP film max. diameter 500mm

OPP film inner diameter of paper tube 75mm-76mm

Bronze paper gilding way by Flat-bed pressing

Gilding plate Copperplate or zinc plate

Max. gilding area 290mm x 300mm ( depends on material )

Feeding length 10mm~300mm

Hot stamping speed 150imp/min

foil deliver ways Stepping motor

Thickness of hot stamping plate Zinc plate 1.2mm , Copper plate 3.0mm

Pressure distance by height 5mm

Max. foil width 300mm

Max. foil diameter 100mm

Inner diameter of foil tube 25mm-26mm

Hot stamping plate fixed: Strong agglutinant.

Die-cut ways:by Flat-bed pressing.

Max. Die-cut area:290mm x 300mm.

Thickness of Die-cut mold: 9mm~12mm

Pressure distance by height: 5mm.

Die-cut mold fixed: by Most strong bond, Double side tape.

Featured products